Is DTF better than sublimation?

Some people still confuse these two terms and generally assume them to be the same. However, they are not. Sublimation printing and transfer printing have differences in how they work.

Sublimation is a technique used to print fabrics containing polyester, unlike transfer printing, a technique that involves printing cotton fabrics, either light or dark colors. Below, we detail the processes for you:

DTF Transfer Printing

This process requires a printer with special pigmented inks to generate better resistance and print on transfer paper. The material to be printed must be cotton fabric. Once the design is printed, the transfer paper is placed on the fabric, then pressure and temperature are applied by means of an iron for a certain time, depending on the transfer paper used.

DTF Pros

- Almost all types of fabrics can be printed with DTF

- No preprocessing required

- The fabric has good washing property.

- Simple process, faster printing speed

DTF Cons

- The feel of the print area is slightly different than that of thermal sublimation printing

- Color brightness is slightly lower than sublimation printing.

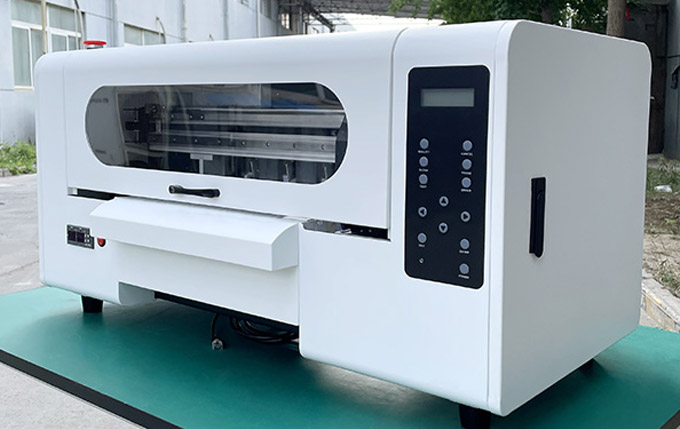

Looking for the best DTF printer?

Want to start t shirt printing business? Textek DTF printer is the best choice for you. DTF printer can for any color, any fabric t shirts, easy operation, make your business improved. Textek DTF printer factory has A3 30cm DTF printer and large size 60cm DTF printer, low cost, big profit.

Sublimation Printing

Sublimation, also called thermofixation, is a process in which the ink is printed on the fabric by means of heat, going from solid to gaseous state without passing through the liquid. For this type of printing it is necessary to use special sublimation inks, a printer adapted to print special sublimation paper and the material to be printed, which must be polyester fabric. Once the image is printed with sublimation ink, the print is placed on the t-shirt on the thermal plate and the printing is done for a certain time, at this moment the sublimation occurs; the solid ink evaporates and is transferred to the fabric by chemical reaction. The result is a stable, durable and high quality chemical bond.

Sublimation Pros

- Sublimation is one of the few methods that exist today that allows printing on rigid supports like cups, photo frames, plates, watches, etc.

- This is a relatively simple technique that you can easily learn to use.

- It allows for an unlimited range of colors. If you use four-color ink, CMYK, you can get thousands of different hues, and there is no cost involved if you want to add new colors to your designs.

- The unit cost is the same whether you print one unit or a thousand, so you don’t need to set a minimum number.

- Through sublimation, print is integrated into the support and becomes part of the support. Unlike transfer paper, the printed design has no sensation to the touch and will not scratch or fade.

Sublimation Cons

- The fabric must be made of 100% polyester, or at least about 2/3 polyester.

- Only special polyester coatings can be used for non-textile substrates.

- Items must have white or light colored printed areas. Sublimation does not work well on black or dark fabrics.

- If permanently exposed to direct sunlight, the color can fade within months due to ultraviolet light.

Differences between sublimation and DTF transfer

The main differences between sublimation and transfer are that sublimation must be printed with synthetic polymer inks on a polymer surface, such as polyester. Sublimation can be used on other materials that have been previously coated with a layer of paint or polymer ink, while transfer can only be done on cotton fabric because if it is printed on another surface it is easily removed.

Another difference is that sublimation on fabrics must be done on white fabric, since sublimation inks are transparent and get contaminated with the colored fabric.