- Print head: EPSON l3200-U1 HD Printhead

- Printing speed: 0.28m²/h~3m²/h

- Print width: Platform:297*420mm

- Print Media: Glass, plates, various signs, crystal, PVC, acrylic, leather plastic, etc.

- Print Media Thickness: 1mm~90mm

- Ink: Environmental friendly UV curing ink

- Color Configuration: Standard: CMYK+W+V

- RIP software: Maintop/Flexiprint/RIIN

- Machine size: L/W/H: 825mm*1019mm*612mm 80KG

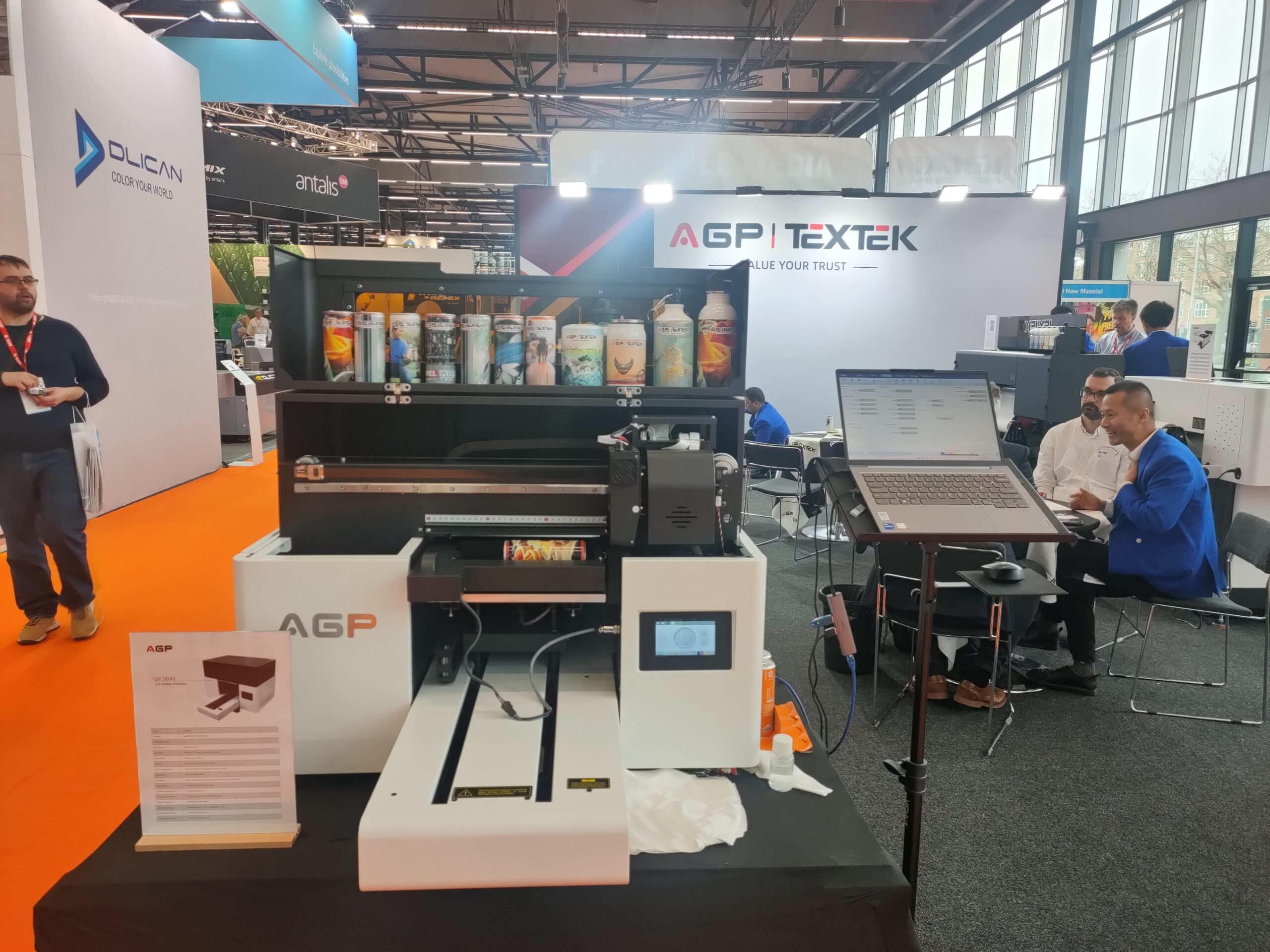

TEXTEK UV Flatbed printer 3040

The TEXTEK UV3040 redefines printing with its versatile functionality for different surfaces such as metal, leather, wood, paper, plastic, ceramics, and glass. Equipped with the Epson I3200-U1 HD printhead, it delivers precise and crisp prints on a 297x420mm platform and 230x420mm cylinder. With a standard color gamut of CMYK+W+V and optional YMCK LC LM+W, this printer delivers vibrant colors and sets a new standard in UV printing technology.

Specification

| Model | UV3040 |

| Printhead | Epson l3200-U1 HD Printhead |

| Printhead Quantity | 1 |

| Print Speed | 0.28m²/h~3m²/h |

| Print Width | Platform:297*420mm Cylinder:230*420mm |

| Print Media Thickness | 1mm~90mm |

| lnk Type | Environmental friendly UV curing ink |

| Color Configuration | Standard: CMYK+W+V Optional: YMCK LC LM+W |

| RIP Software | Maintop, FlexiPRINT,RIIN |

| Print Media | Glass, plates, various signs, crystal, PVC, acrylic, leather plastic, etc. |

| Photo Format | TIFF, JPEG, PDF, EPS, PNG, Al, BMP, etc. |

| Computer Configuration | Win10/64-bit system |

| Transmission Interface | Gigabit network port, hard disk 500G above |

| Rated Voltage/Power | 220V,50HZ/60HZ |

| Sleeping:30WWorking:500W | |

| Work Environment | T:15°C~28°C, H: 40%~60%RH |

| Machine Size/Weight | 825mm*1019mm*612mm(L*W*H) 80KG |

UV Printing Technology

Features of A3 Pro DTF Printer

- The UV3040 is a powerhouse of functionality designed to revolutionize your printing experience. Its versatile capabilities extend to printing on a wide range of surfaces, from metal and leather to wood, paper, plastic, ceramics, and glass. Equipped with the advanced Epson L3200-U1 HD print head, it ensures precision and clarity in every print.